Industrial

Technology and know-how at your serviceIndustrial Division

the Industrial Division of Plax Group co-develops, engineers and produces high-performance, custom plastic parts for the OEM market (automotive, aerospace, construction, home automation, electronics, vending).

Know-how

and expertise

Plastic Mechatronics

This is the family of products that allow the acquisition or transmission of a signal or an input.

The main products Plax produces include sensors, connectors, coils, actuators, knobs and technical housings.

Kinematics and transmission systems

This includes components made of special technopolymers capable of transmitting or transforming a mechanical movement.

The Plax Industrial Division has extensive experience in producing products such as bearing washers, clutches, pulleys, gears, etc.

Fluid management

This is the family of products capable of transferring any fluid material - air, water, oil, fuel, etc. - and/or making it air/watertight.

The multiple applications at Plax include housings for pumps, hydraulic blocks, connectors, gaskets, cylinders, fins, etc. These products are made with specific polymers certified for each application.

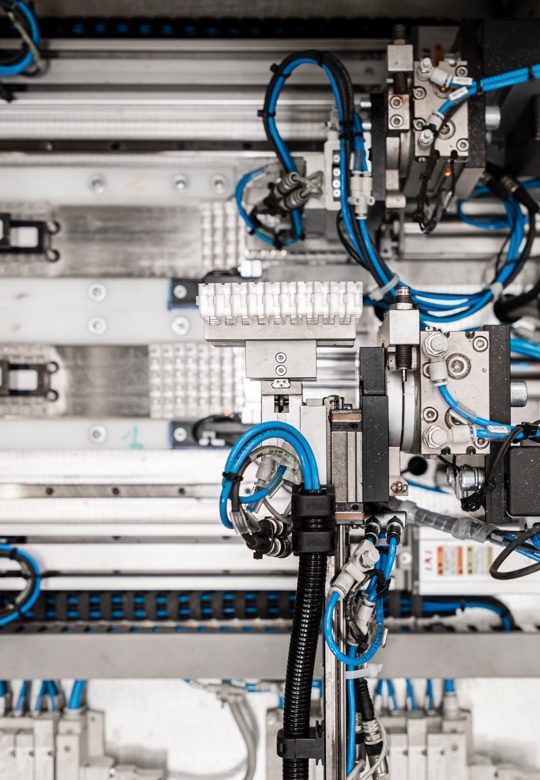

Technologies

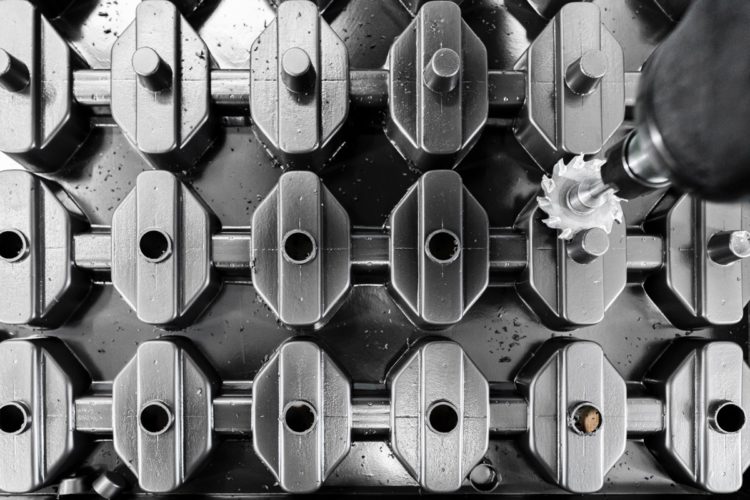

Injection molding of highly quality precision industrial parts for small, medium and large scale production.

BI-INJECTION molding involves the injection of two different materials, at the same time, within the same cavity but through two different nozzles.

This technique involves the use of one or more inserts inside the mold. After completing the injection of the first material , the inserts in the mold are moved so as to create the space necessary inside the cavity for the injection of the second material.

This is a two-component liquid silicone rubber for the production of articles with elastic properties using injection molding.

Raw materials used

Basic technical thermoplastics

PA, PBT, POM, ABS

High temperature materials

PPA, PPS, ecc.

Other technical polymers

PEEK, LCP, PSU, ecc.

Elastomers

silicone, TPU, TPE, ecc.

Services