Rapid Prototyping

Rapid prototyping is an excellent solution technology for creating three-dimensional models of a single part or an entire product. This technology is used to perform a preventive test on the efficiency of the product and material before mass production.

What are the main advantages of rapid prototyping technology:

Rapid prototyping is chosen because it involves a series of indisputable advantages that optimize production times and costs.

Indeed, the application of rapid prototyping provides:

- Easy identification and correction of critical issues before production;

- Greater ease in making changes thanks to additional construction;

- Reduced risk of construction during production;

- Minimum initial costs for the creation of the necessary molds and tools;

- Huge reduction in design defects;

- General optimization of costs and times.

Plax solutions for rapid prototyping:

Plax offers different solutions and techniques for rapid prototyping, designed to best meet customer needs.

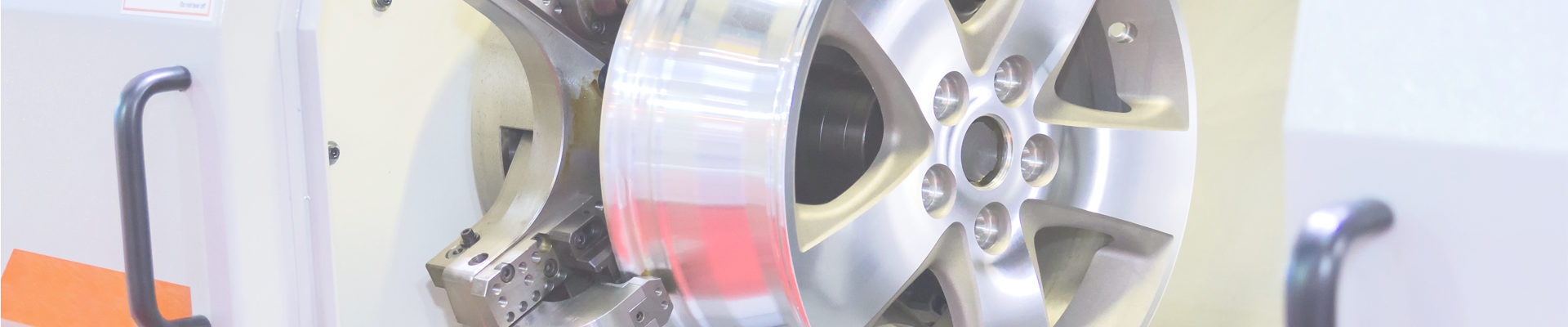

CNC Solid milling

Mechanical machining with very high-precision 5-axis CNC machines, even for the production of single pieces.

Dimensional report upon request.

MATERIALS: ALUMINIUM 5000-6000-7000 series, POM, ABS, NYLON, NYLON 30% glass fibre reinforced

BRASS, TEFLON, STEELS, PMMA, POLYCARBONATE.

FINISHES: machine, smooth, glossy, chrome, painted, sandblasted.

STEROLITHOGRAPHY (SLA)

Stereolithography produces three-dimensional objects directly from STEP - IGES - STL file digital data

This rapid prototyping technique is ideal for technical-cosmetic prototypes and

for subsequent finishing and colouration.

High dimensional accuracy.

Precision X and Y 0.2 mm

Maximum monolith size:

1000x1000x2000 mm;

MATERIALS: Transparent or white

Selective Laser Sintering (SLS)

Sintering produces three-dimensional objects directly from STEP - IGES - STL file digital data.

Excellent quality-price ratio

Precision X and Y 0.5 mm

This rapid prototyping technique is ideal for technical-cosmetic prototypes,

ideal for technical prototypes where no surface finish is required,

Maximum monolith size 680x370x550 mm;

MATERIALS : Nylon, Nylon+glass, Nylon+PA11, PA12, PA6 and TPU based aluminium powder

SILICONE MOLDS

Rapid prototyping technology particularly useful for production (Replicas) of small and medium series with virtually identical pieces to the final ones.

MASTER produced with either SLA or CNC Maximum monolith size: 1000x1000x2000 mm

MATERIALS: Polyurethane resins that can also be mass-coloured , ABS-like, PA-like, PP-like, transparent PMMA / PC

25-35-50-60-80 shA RUBBER.

Option of co-molding

METAL SLS:

Rapid prototyping technique ideal for technical metal prototypes.

Sintering of Aluminum, Steel, Titanium or Chromium-Cobalt powders; with the use of one or more very high power lasers, we produce geometrically complex metal objects, with density similar to precision casting.

Maximum dimensions 800x400x500 mm

Precision X and Y 0.5 mm

OBJET

High resolution rapid additive prototyping technology that produces

cosmetic prototypes in different materials and colours already in the production phase.

Precision X and Y 0.2 mm

Maximum dimensions 490x390x200 mm

Fused Deposition Molding (FDM)

Rapid prototyping technique.

Technology that creates three-dimensional objects in real final layered material.

Mechanical characteristics comparable to injection molded pieces, even in co-molded bi-material.

Maximum dimensions 900x600x900 mm

Precision X and Y 0.2 mm

MATERIALS : ABS, PC, ULTEM, PP

FINISHES

In rapid prototyping, the finishes are used to enhance the parts with colours and finishes, which make the prototype object identical to the final object in cosmetic appearance; they are ideal for cosmetic pieces and presentations

Metallization, chrome plating, painting, sandblasting, polishing